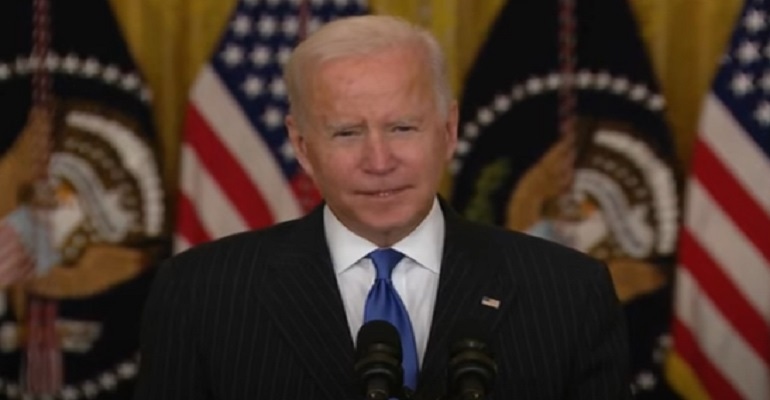

How to Solve Supply Chain Issues? Biden Orders Ports to Open 24/7

In an attempt to overcome supply chain bottlenecks, President Biden asks Southern California ports to operate around the clock.

October 14, 2021

I need a snake to unplug my kitchen sink. Should be an easy overnight fix. Turns out I have to wait two weeks for a snake. My tiny personal issue is getting played out on a mega-scale across the globe as supply chain bottlenecks stymie the flow of goods from semiconductor chips to toys from Asia. If you think things are bad now, wait until the Christmas rush hits.

In an effort to keep goods flowing, the White House announced it has asked for increased capacity at major California ports. In a briefing Wednesday, President Biden announced that the Port of Los Angeles has agreed to double its hours and move to 24/7 operations. The Los Angeles port joins the Port of Long Beach, which launched nighttime and weekend shifts weeks ago. More than 40% of goods enter the US through those two ports.

The Clogged California Ports

In recent weeks the backlog of ships needing to unload at the Los Angeles and Long Beach ports hit new records. This week, 65 cargo ships were in line off of the coast waiting to dock and unload. The two ports are the largest shipping complex in the Western Hemisphere, making them some of the busiest in the world.

In his briefing Wednesday afternoon, Biden referenced agreements the White House has brokered with private sector entities to get goods flowing again. “We need to take a longer view and invest in building greater resiliency to withstand the kinds of shocks we’ve seen over and over, year in and year out, the risk of a pandemic, extreme weather, climate change, cyberattacks, and weather disruptions,” said Biden.

The Deadly Delta Variant

This spring, companies were beginning to cope with several supply chain issues, bringing back furloughed workers and inching toward some new kind of normal. Then the Delta variant of coronavirus hit unexpectedly, putting added stress on the nascent recovery in the flow of goods. One manufacturer said it is now taking 80 days to move shoes from Asia to the US. That’s twice as long as it took in the past. The issue is port bottlenecks, container shortages, rail congestion, and a shortage of labor to unload goods.

Manufacturers are also facing increased demand from consumers who became cash-rich through government subsidies during the pandemic. That has been compounded by worker shortages along the supply chain, from truck drivers to warehouse employees to dock workers. While the administration can’t order a mess to not be a mess, the request for longer hours at ports could help Santa keep his promise to deliver toys for Christmas.

About the Author(s)

You May Also Like