AI Fires Up Materials Informatics

The relatively new field of materials informatics has been bolstered by the recent appearance of AI programs such as ChatGPT.

March 6, 2024

At a Glance

- Advances in materials development

- AI accelerates materials informatics

- Materials have become core to technical advances

The development of new materials has been booming in recent years, driven by innovations in aerospace, medical, and 3D printing applications. According to TrendFeedr, the materials sector is leading the charge in technological advancement. Advances in materials science are revolutionizing manufacturing and product design. These innovations are also contributing to sustainability and efficiency.

TrendFeedr notes that pioneering materials such as self-healing polymers and graphene, are providing answers to pressing challenges. The aerospace industry is integrating advanced composites that reduce aircraft weight while improving performance and fuel efficiency. In electronics, conductive inks enable flexible, wearable technology. The medical field is experiencing significant shifts with the introduction of biocompatible materials that improve prosthetics and implantable devices.

These advances have resulted in a critical change in the function of materials – evolving from mere components of products to essential contributors to performance and innovation.

Here Comes Materials Informatics

The emergence of materials informatics (MI) is helping the development of new materials. MI refers to the efforts to improve the efficiency of material development, using data and computational science methods that include vast amounts of experimental data, material data, and AI – both machine learning and deep learning.

MI aims to achieve high-speed and robust acquisition, management, analysis, and dissemination of diverse materials data with the goal of greatly reducing the time and risk required to develop, produce, and deploy new materials. In the past, the process has taken as long as 20 years or more.

MI's history dates from 2011, when data-driven materials development started in the US. It then spread worldwide. In Japan, the Information Technology Initiative for Materials and Materials Development was launched in 2015.

Digitization has made it possible to manipulate vast amounts of data with supercomputers and other high-performance information processing equipment. This has resulted in the acceleration in predicting the molecular structure and manufacturing methods of materials.

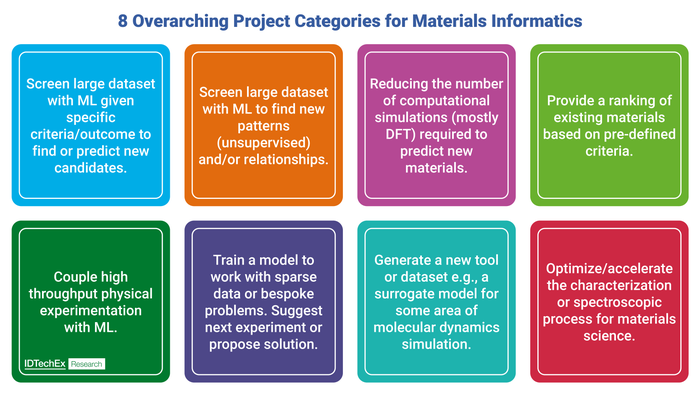

Image courtesy of IDTechEx.

Hitachi started to provide material development solutions in 2017. Hitachi noted that MI is a data-driven development, “We will be able to take the data and make the next move, rather than relying on the experience and intuition as in the past,” the company said in a statement. “It can be applied not only in material development but also in various fields, and we can expect to improve the efficiency of development.”

MI Report Released by IDTechEx

Over the past year, developments in artificial intelligence have given MI a boost. IDTechEx has released the report, Materials Informatics 2024-2034: Markets, Strategies, Players, which looks at advances in materials informatics that are driven by the expanding availability of AI.

IDTechEx’s report notes that generative AI was being used in materials informatics far before the term became widely known to the public. Yet the impact of generative models expanded significantly in 2023 with the newly powerful large language models (LLMs) behind services like ChatGPT.

LLMs are pushing changes to materials informatics. The IDTechEx report lays out the potential of LLMs in materials research. One impact is the potential expansion of the customer base of materials informatics software to materials end-users by flattening learning curve and using natural language as an interface.

The report notes that adopting MI usually takes several core approaches: operate fully in-house, work with an external company, or join forces as part of a consortium or joint venture. Major players like Hitachi have previously offered in-house developed materials informatics platforms externally.

A new approach emerged in 2023. Henkel spun off its end-to-end research platform Albert Invent as an external company, continuing to engage it as a customer while allowing the startup to grow as a more agile but very well-funded smaller organization. Perhaps 2024 could see more similar spin-offs as companies seek to gain even more ROI from their in-house developed platforms while avoiding the conflict of interest of engaging with competitors themselves.

About the Author(s)

You May Also Like